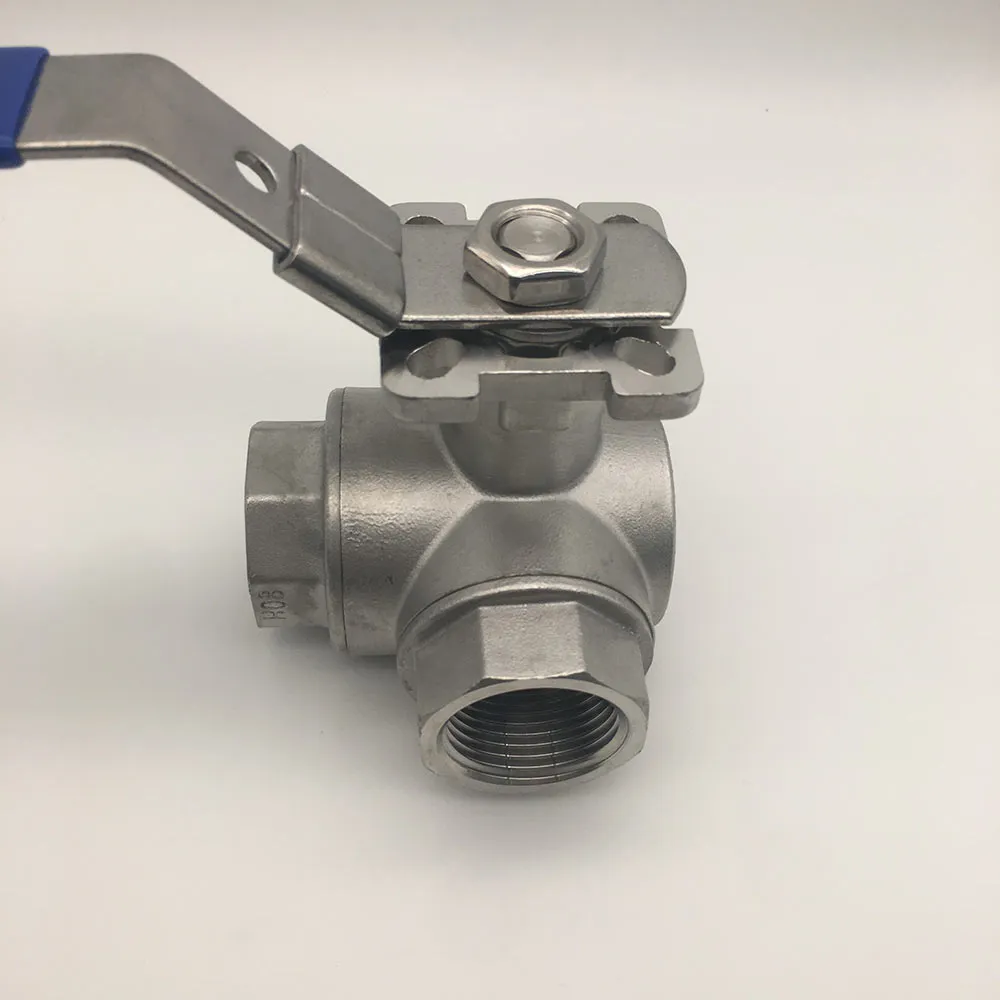

3-Way Ball Valve With Direct Mounting Pad

The stainless steel three-way ball valve is an efficient valve specially designed for complex fluid control systems. It is made of high-quality stainless steel (SS304/SS316) and features outstanding corrosion resistance, high temperature resistance and mechanical strength. Its unique three-way structure (L-shaped or T-shaped flow channels) enables the function of fluid diversion, confluence or flow direction switching. It is widely used in industrial processes that require multi-directional control.

Core Features

1. Multi-functional Flow Channel Design

- L-shaped Flow Channel: Achieves fluid switching from two inlets to one outlet through a 90° turn, suitable for medium distribution or flow direction alteration.

- T-shaped Flow Channel: Supports three-way flow, enabling confluence, diversion, or straight-through mode, meeting the requirements of complex pipeline layouts.

- Full-diameter or Reduced-diameter Design: Optional full-diameter structure to reduce pressure loss, or reduced-diameter design to optimize space occupation.

2. High-performance Materials and Manufacturing Techniques

- Valve Body Material: Stainless steel SS304/SS316, resistant to corrosion and acid-base, suitable for extreme temperature and chemical environments.

- Sealing Components: PTFE (Polytetrafluoroethylene) or metal hard seals, ensuring zero leakage and long service life.

- Explosion-proof Valve Stem: Extended valve stem design, anti-static and anti-blowout, suitable for high-pressure working conditions.

3. Flexible Operation and Adaptability

- Operation Mode: Manual lever/handwheel (standard configuration), and optional pneumatic, electric or hydraulic actuators can be selected for achieving automated control.

- Connection Method: Threaded (NPT/BSP), flange, welding (socket weld/ butt weld).

- Port Configuration: Supports one inlet and two outlets, two inlets and one outlet, or three-way circulation, meeting diverse system requirements.

Technical Specifications

- Pressure Range: PN16 to PN40, Class 150 to Class 300 (up to 1000 PSI at the maximum).

- Temperature Range: -29℃ to +200℃ (PTFE seal).

- Pipe Diameter Range: DN15 to DN200 (1/2" to 8"), customizable as per customer's requirements.

- Applicable Media: Water, steam, oil products, gases, corrosive liquids and high-purity fluids.

Typical Application Scenarios

- Industrial Processes: Chemical reaction vessels, heat exchange systems, cooling circulation pipelines, mixing equipment.

- Energy Sector: Oil and gas transportation, boiler control, compressed air systems.

Product Advantages

- Reliable Sealing: Bidirectional pressure-bearing design, bubble-level sealing performance.

- Easy Maintenance: Modular structure enables quick disassembly and assembly, reducing downtime.

- Economical and Efficient: One valve for multiple uses, simplifying pipeline layout and lowering overall costs.

Packaging and Delivery

- Packed into carton box. For large quantities, it is transported in reinforced veneer cases.

- Original factory material report and third-party test certificate (as per demand) are provided.

Customized Services

Support for non-standard dimensions, special surface treatments (electrolytic polishing, EP grade), oil-free degreasing packaging and other personalized requirements.

For details, please contact the technical team!

3-Way Ball Valve Flexible Operation And Fast Switching

The Three-Way Ball Valve Supports Multiple Flow Combinations (Such As L-Type Or T-Type Channels), Which Can Realize The Functions Of Fluid Diversion, Confluence, And Reversal. Compared With Traditional One-Way Valves, One Valve Can Replace Multiple Ordinary Valves, Greatly Simplifying The Piping System And Saving Space And Cost.

Click The Button Below To Easily Purchase →

High Quality Stainless Steel, Quality Life Starts Now!