Products

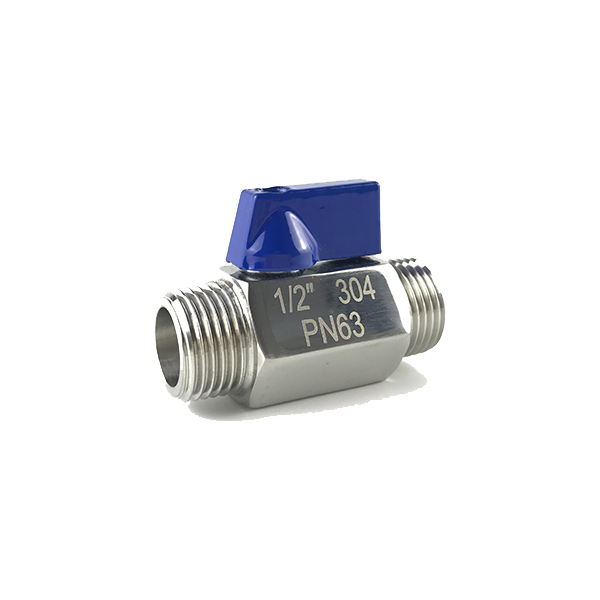

Stainless steel valves, with their outstanding material and structural advantages, are widely used in multiple industries such as petroleum, chemical engineering, pharmaceuticals, food, papermaking, and water treatment, and have become indispensable important components in modern industrial fluid control systems. Its most notable advantage lies in its strong corrosion resistance. Made of 304, 316 or higher grade stainless steel, it can effectively resist corrosive media such as acids, alkalis and salts, making it suitable for high-demand working environments. Stainless steel valves possess outstanding mechanical strength and high-temperature resistance, enabling them to operate stably for a long time under high-pressure and high-temperature conditions without deformation or leakage, significantly extending their service life. Its structural design is precise and its sealing performance is excellent, ensuring the safety and efficiency of medium transportation, and reducing maintenance costs and operational risks. Stainless steel valves also have a good appearance and texture, with a smooth surface that is not prone to dirt accumulation, meeting the strict cleanliness requirements of the food and pharmaceutical industries. Meanwhile, it has strong versatility and can be matched with various flange, threaded or welded interfaces. It is easy to install and maintain. Stainless steel valves are high-quality fluid control products that integrate high performance, high reliability and high adaptability, and they are an important guarantee for achieving industrial automation and safe production.

Click The Button Below To Easily Purchase →

High Quality Stainless Steel, Quality Life Starts Now!