Understanding the Significance of 3 way valve l type in Industrial Applications

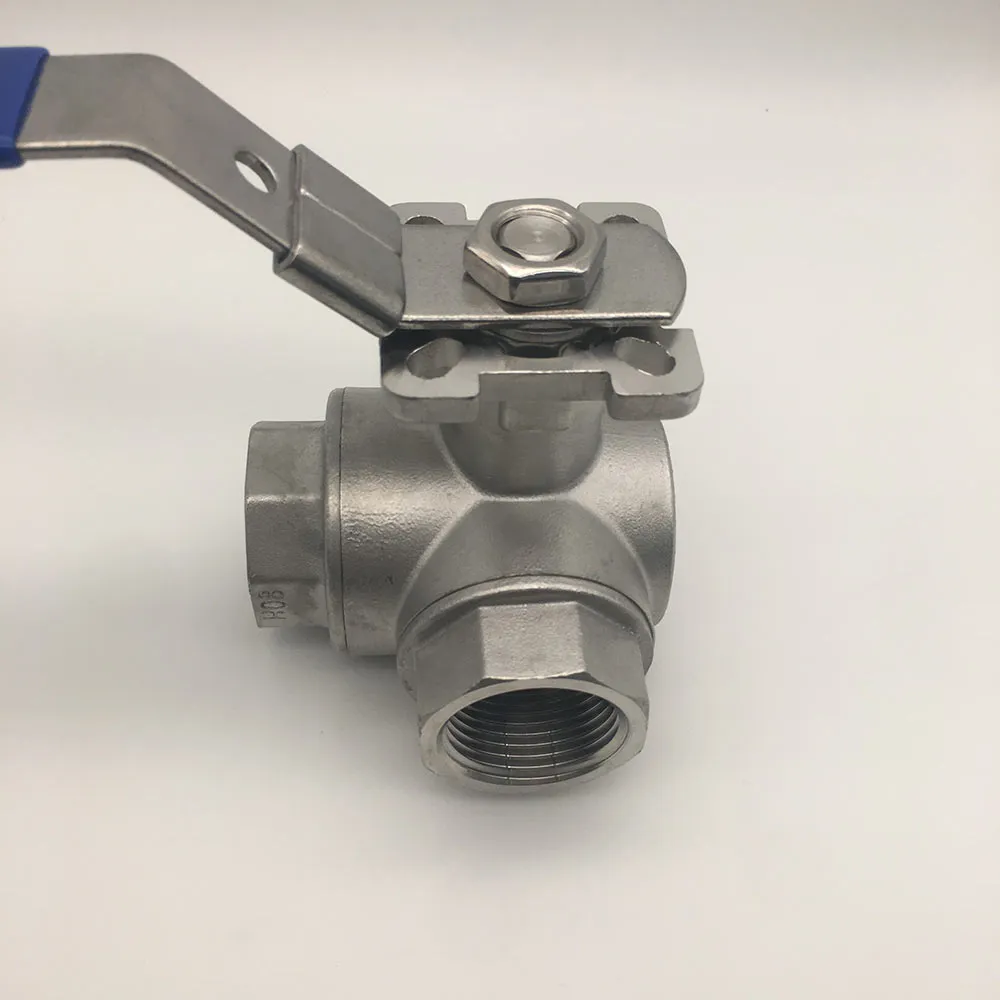

In the intricate world of industrial fluid control, the selection of appropriate valve technology is paramount to operational efficiency, safety, and longevity. Among the myriad options, the 3 way valve l type stands out as a critical component, primarily recognized for its unique ability to divert or combine flow paths within a piping system. This specific configuration, distinct from its T-type counterpart, facilitates a straightforward 90-degree flow change or diversion from one inlet to either of two outlets, proving indispensable in scenarios requiring selective routing rather than mixing. Modern industrial trends underscore a growing demand for compact, highly reliable, and easily maintainable valve solutions, a niche perfectly filled by the 3-Way Ball Valve With Direct Mounting Pad. These valves are engineered to meet stringent industry standards, offering superior performance in a wide array of demanding environments, from high-pressure pipelines to corrosive chemical processing lines. Their increasing adoption is driven by a collective industry push towards automation, sustainability, and enhanced operational safety, where precise flow management is non-negotiable. Furthermore, as industries globalize and supply chains become more complex, the availability of high-quality 3 way ball valve for sale that adheres to international certifications like ISO 9001, API, and ANSI becomes a decisive factor for procurement managers. This ensures not only functional compatibility but also compliance with global safety and environmental regulations, contributing significantly to a project's overall success and return on investment in an increasingly competitive marketplace. The ability to integrate seamlessly with various actuation systems, whether manual, pneumatic, or electric, further solidifies the L-type 3-way valve's position as a versatile and future-proof choice for diverse industrial requirements.

Manufacturing Excellence: The Process Behind the 3 way valve l type

The production of a high-performance 3 way valve l type involves a meticulous multi-stage manufacturing process, beginning with the selection of premium materials to ensure durability and resistance to specific operating conditions. Commonly used materials include stainless steel (304, 316, 316L) for corrosion resistance, carbon steel (A216 WCB) for general industrial applications, and specialized alloys for extreme temperatures or highly aggressive media. The manufacturing journey typically commences with precision casting or forging, where molten metal is poured into molds or metal billets are hammered into shape to create the valve body, end caps, and ball. These initial steps are critical for establishing the structural integrity and basic geometry of the valve components. Following this, advanced CNC (Computer Numerical Control) machining takes over, transforming raw castings or forgings into precise components with tight tolerances. This stage ensures the accurate shaping of the valve bore, seat pockets, and mounting pads, which are vital for achieving leak-tight sealing and smooth operation. The direct mounting pad, in particular, adheres to ISO 5211 standards, ensuring universal compatibility with various actuators. Subsequent processes involve critical treatments such as surface finishing, which can include polishing or special coatings to enhance corrosion resistance and reduce friction, thereby extending the valve's operational lifespan. Assembly is then performed in a clean environment, where the meticulously machined ball, seats (often PTFE, PEEK, or Reinforced PTFE for different temperature/pressure ratings), stem, and packing materials are integrated. Each valve undergoes rigorous inspection and testing, adhering to international standards like API 598 for pressure testing (hydrostatic and pneumatic tests for seat and shell integrity), ANSI B16.34 for valve design, and ISO 15848-1 for fugitive emissions, which is crucial for environmental compliance in industries like petrochemicals and oil & gas. This comprehensive quality assurance regimen ensures that every 3 way valve l type delivered meets or exceeds the specified performance criteria, guaranteeing reliability and a long service life, typically exceeding 10,000 cycles, and contributing to significant energy savings by minimizing pressure drops and preventing costly leaks in demanding applications such as chemical processing, water treatment, and power generation facilities, where corrosion resistance is paramount for long-term operational integrity.

Technical Specifications and Performance Advantages

The technical prowess of the 3 way valve l type is best understood through its precise specifications and the unique advantages it offers over other valve configurations. These valves are distinguished by their specific bore configuration, which allows for either flow diversion (from a common inlet to one of two outlets) or selection (from one of two inlets to a common outlet), but crucially, they do not allow flow between all three ports simultaneously, unlike a 3 way valve t type. This makes them ideal for applications requiring selective flow path management, such as diverting flow from a main line to a bypass or routing fluid to different process tanks. Key technical parameters include the nominal size (ranging from DN15 to DN300, or ½ inch to 12 inches), pressure rating (typically PN16, PN25, PN40, or Class 150, 300, 600), and temperature range, which is largely dependent on the chosen body and seat materials. For instance, PTFE seats typically handle temperatures up to 200°C (392°F), while PEEK can withstand much higher temperatures up to 260°C (500°F) and higher pressures. The integral direct mounting pad, conforming to ISO 5211, simplifies automation by allowing direct mounting of actuators without the need for additional brackets, reducing both complexity and potential leak points. This design significantly enhances the valve’s operational efficiency and reduces installation time and costs. Furthermore, the robust construction of a 3 piece ball valve design often incorporates features like blow-out proof stems, anti-static devices, and fire-safe designs (API 607/BS 6755 Part 2 certified), providing enhanced safety and reliability in critical applications. The precise machining and tight tolerances achieved during manufacturing ensure minimal leakage and low operating torque, contributing to energy efficiency by reducing the power required for actuation and enhancing overall system stability. The versatility of end connections—flanged, threaded, or welded—allows seamless integration into diverse piping systems, reinforcing the L-type valve's status as a highly adaptable and essential component in modern industrial infrastructure. This combination of precise engineering and robust material selection underpins the valve's reputation for long-term, trouble-free service in challenging operational environments.

| Parameter | Typical Range/Value |

|---|---|

| Nominal Size (DN/Inches) | DN15-DN300 (½" - 12") |

| Pressure Rating | PN16/25/40; Class 150/300/600 |

| Body Material | SS304, SS316, WCB, Duplex Stainless Steel |

| Ball & Stem Material | SS304, SS316, SS316L |

| Seat Material | PTFE, RTFE, PEEK, Delrin |

| Temperature Range | -20°C to 260°C (Material Dependent) |

| End Connections | Flanged (ASME B16.5), Threaded (NPT, BSP), Welded (BW, SW) |

| Actuation | Manual (Lever/Gear), Pneumatic, Electric |

| Design Standard | API 608, ASME B16.34 |

| Face to Face | ASME B16.10 |

Diverse Application Scenarios and Manufacturer Comparison

The versatility of the 3 way valve l type makes it a staple across a multitude of industrial sectors. In the petrochemical industry, these valves are crucial for diverting hydrocarbons, managing product blending lines, and isolating sections for maintenance without disrupting the entire process, where their robust construction and fire-safe certifications are paramount. For water treatment facilities, they facilitate the controlled routing of treated water or wastewater to different filtration units or discharge points, ensuring efficient and compliant operations. In the metallurgy sector, especially in steel mills, L-type valves are employed for managing cooling water systems or diverting abrasive slurries, requiring materials highly resistant to wear and tear. Furthermore, in pharmaceutical and food & beverage industries, their hygienic design (often with polished internal surfaces and FDA-compliant seat materials) enables precise routing of sensitive media, preventing contamination and ensuring product integrity. When considering a 3 way ball valve for sale, comparing manufacturers is vital, focusing on their adherence to international quality standards, years of experience, and their ability to provide comprehensive technical support and after-sales service. Reputable manufacturers like Houde Valve, with decades of experience, distinguish themselves through strict quality control, including 100% in-house testing and traceable material certifications. Unlike some competitors who might compromise on material quality or machining precision to reduce costs, leading to shorter lifespans and increased maintenance, a proven manufacturer invests in advanced manufacturing technologies like precision CNC machinery and utilizes top-grade raw materials certified to ASTM or EN standards. This commitment ensures superior performance, longer operational lifecycles, and greater safety margins, reducing the total cost of ownership over the valve's lifespan. Factors such as a manufacturer's global footprint, success stories with major clients, and certifications (e.g., ISO 9001 for quality management, CE for European markets, API for oil and gas applications) are strong indicators of reliability and authority. Ultimately, the choice often boils down to a balance between initial investment and long-term reliability, where opting for a trusted supplier of 3 way valve l type ensures peace of mind and operational continuity.

| Feature | L-Type Port Configuration | T-Type Port Configuration |

|---|---|---|

| Flow Diversion/Mixing | Primarily for flow diversion or selection (90° path change). Cannot mix all three ports simultaneously. | Can divert flow or mix flow from two inlets to a common outlet, or allow straight-through flow. Allows flow between all three ports in one position. |

| Application Suitability | Bypass lines, tank selection, diverting media to different process streams. | Mixing applications, line switching, complex manifold systems, situations requiring simultaneous flow from multiple sources. |

| Operational Complexity | Simpler flow control, less prone to mis-operation in basic diversion tasks. | More complex flow management; requires careful consideration of flow paths. |

| Typical Use Cases | Switching between filters, directing flow to different storage tanks, single-source branching. | Combining chemical streams, temperature control loops with bypass, intricate manifold designs. |

Custom Solutions and Real-World Application Cases

While standard 3 way valve l type models cater to a broad range of industrial needs, specific applications often necessitate custom solutions to meet unique operational parameters. This can involve specialized materials for extreme corrosive environments, higher pressure/temperature ratings beyond standard limits, or integration with specific control systems. Customization frequently extends to different end connections, such as specialized flange drilling patterns, or the inclusion of bypass lines and purging ports for maintenance. For instance, in an offshore oil and gas platform, a customized 3 piece ball valve with a unique L-type flow path, constructed from Duplex stainless steel and equipped with high-temperature PEEK seats, might be engineered to manage corrosive well fluids at elevated pressures, ensuring maximum integrity and extended service life in a highly challenging marine environment. Another compelling application case involves a large-scale pharmaceutical plant that required a specialized L-type valve with ultra-high purity internal finishes and CIP/SIP (Clean-in-Place/Sterilize-in-Place) capabilities to divert purified water between various processing vessels without any risk of contamination. This demanded specific surface roughness requirements (e.g., Ra

Ensuring Trustworthiness: FAQ, Delivery, and Warranty

Establishing trust in the B2B sector, particularly for critical components like the 3 way valve l type, goes beyond just technical specifications; it encompasses transparency, reliable logistics, and unwavering customer support. Companies often have common questions when procuring industrial valves. For instance, a frequently asked question is: "What is the typical lead time for a standard 3 way valve l type?" For standard configurations and sizes, reputable manufacturers typically quote a delivery cycle of 4-6 weeks, though this can vary based on order volume, material availability, and current production schedules. For custom orders or specialized materials, lead times may extend to 8-12 weeks, with clear communication throughout the process. Another common query revolves around installation and maintenance: "Are special tools required for installation or routine maintenance?" Generally, standard tools suffice, but detailed installation and maintenance manuals, often available digitally or in print, provide step-by-step guidance. Manufacturers also commonly address questions regarding material compatibility with specific media, providing comprehensive material selection guides based on chemical resistance data and industry standards. Regarding quality assurance, a standard warranty commitment from a trusted supplier usually covers manufacturing defects for 12 to 18 months from the date of shipment or installation, whichever comes first. This warranty reflects the manufacturer's confidence in their product quality and provides reassurance to the client. Post-sale, access to responsive technical support, including field service engineers for complex issues or online diagnostic assistance, is crucial. Moreover, a robust spare parts program ensures that critical components like seats, seals, and packing can be easily replaced, extending the operational life of the valve and minimizing downtime. Comprehensive documentation, including material test reports, hydrostatic test certificates, and compliance declarations (e.g., PED, ATEX), are routinely provided to ensure complete traceability and adherence to international regulations. These elements collectively build a foundation of trust, reinforcing the supplier's reliability and their commitment to long-term client relationships for vital industrial components like the 3 way ball valve for sale.

References

- American Society of Mechanical Engineers (ASME). _ASME B16.34: Valves – Flanged, Threaded, and Welding End_.

- American Petroleum Institute (API). _API Standard 608: Metal Ball Valves—Flanged, Threaded, and Welding End_.

- International Organization for Standardization (ISO). _ISO 5211: Industrial valves – Multi-turn valve actuator attachments_.

- International Organization for Standardization (ISO). _ISO 9001: Quality management systems – Requirements_.

- Valve Manufacturers Association of America (VMA). _The Valve Handbook: A Comprehensive Guide to Industrial Valves_.