The Pivotal Role of 3-Way Ball Valves in Industrial Flow Management

In the intricate world of industrial fluid dynamics, the precision and reliability of flow control components are paramount. Among these, the 3-way ball valve stands out as a versatile and indispensable device, particularly in applications requiring flow diversion, mixing, or selection. This comprehensive article delves deep into the specific advantages, technical intricacies, and widespread applications of the 3 way valve l type, a critical component engineered for robust performance and operational efficiency. Unlike conventional 2-way valves, the 3-way configuration offers unparalleled flexibility in managing complex fluid paths, significantly reducing the need for multiple valves and associated piping. We will explore how these valves, often sought after as a "3 way ball valve for sale" by industries globally, contribute to streamlined operations, enhanced safety, and substantial cost savings. The L-type bore configuration, specifically designed for diverting flow from one inlet to either of two outlets, or for isolating one path while opening another, plays a crucial role in systems where fluid direction needs to be precisely controlled without intermixing different streams, making it distinct from its counterpart, the 3 way valve t type, which allows for broader mixing or through-flow capabilities. This distinction is vital for engineers and procurement specialists when selecting the optimal valve solution for their specific process requirements. Furthermore, the discussion will encompass the robust construction typified by a 3 piece ball valve design, which offers ease of maintenance and in-line repair, extending the service life and reducing downtime in demanding industrial environments. Our objective is to provide a holistic understanding of the L-type 3-way ball valve, underpinned by technical expertise, real-world application insights, and data-driven analysis to empower informed decision-making for B2B stakeholders. The intricate design of these valves allows for seamless integration into complex systems, providing a single point of control for operations that would otherwise require a manifold of individual valves, thereby simplifying piping layouts and reducing potential leak points. This integration is particularly valuable in space-constrained environments or where system compactness is a design priority. The efficiency gains from using an L-type valve, by minimizing pressure drops and optimizing flow paths, directly translate into energy savings and improved process throughput, contributing significantly to operational profitability. The reliability of these valves, often tested to rigorous international standards, ensures consistent performance even under extreme conditions of pressure, temperature, and corrosive media, safeguarding both personnel and critical assets. As industries continue to evolve towards more automated and precise control systems, the importance of reliable and highly functional valves like the 3 way valve l type will only continue to grow, solidifying its position as a cornerstone of modern fluid management.

Understanding the Mechanics: What is a 3 way valve l type?

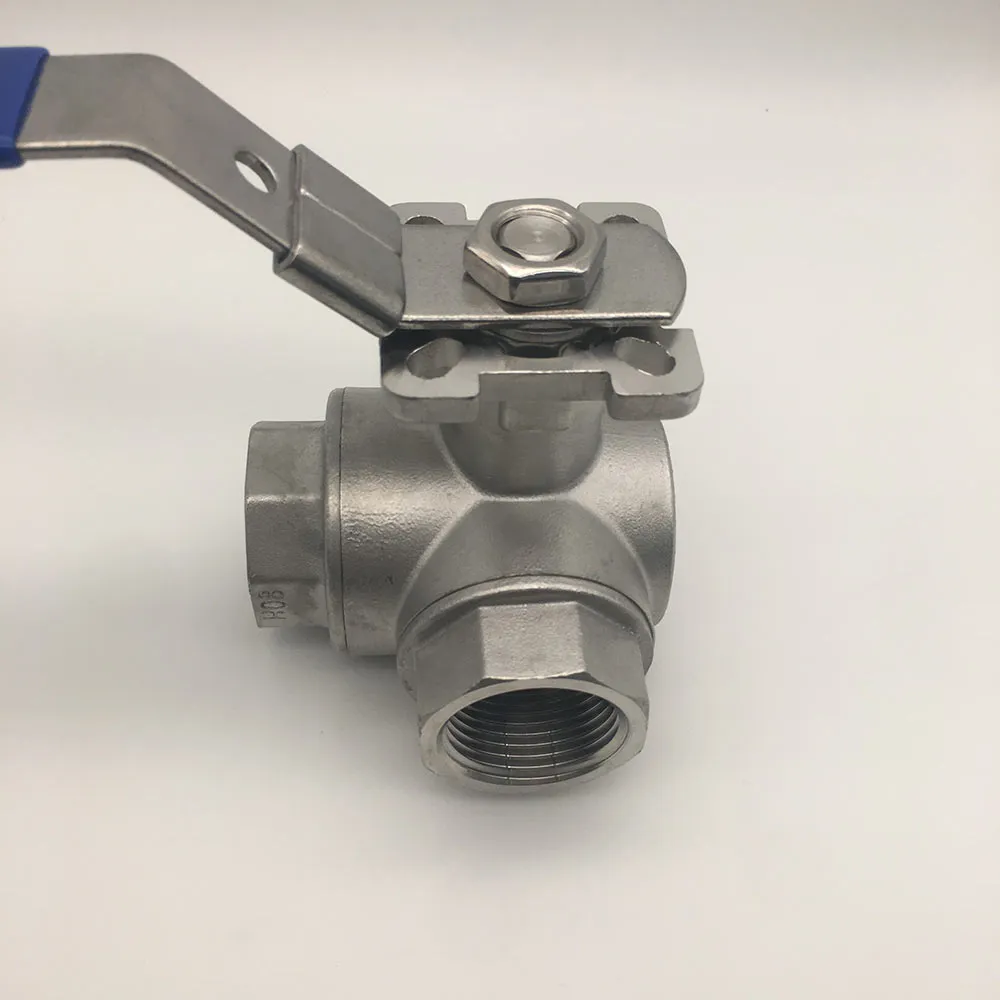

At its core, a 3 way valve l type, often referred to as an L-port or L-bore ball valve, is characterized by its unique internal bore configuration within the spherical ball. Unlike a straight-through (2-way) valve or a T-port 3-way valve, the L-port allows for fluid flow in two distinct 90-degree paths, enabling the diversion of flow from a single inlet to either of two outlets, or the selective isolation of one path while another remains open. This specific design is crucial for applications where fluids need to be redirected without mixing, such as diverting a process stream to a bypass line, selecting between two different supply lines to a single destination, or directing flow to different tanks. The "L" shape of the bore means that when the valve is in one position, flow might go from port 1 to port 2. When rotated 90 degrees, flow will then go from port 1 to port 3, while port 2 is isolated. This mechanical simplicity, combined with robust construction, makes the L-type valve a preferred choice for numerous industrial processes where precise flow management is essential. The nomenclature "ball valve" refers to the spherical closure element with a bore through its center, which rotates within the valve body to control flow. The efficiency of a ball valve stems from its quarter-turn operation, allowing for quick opening and closing, and its excellent sealing capabilities, often achieved with PTFE or PEEK seats, ensuring bubble-tight shut-off. Understanding the distinction between full bore and reduced bore versions is also critical; a full bore valve maintains the same internal diameter as the pipe, minimizing pressure drop and maximizing flow capacity, while a reduced bore valve has a smaller internal diameter, leading to a higher velocity fluid and potentially lower cost for less critical applications. When selecting a 3 way valve l type, engineers must meticulously consider the required flow paths, pressure ratings, temperature limits, and the chemical compatibility of the valve's materials with the media being handled. The L-type configuration inherently prevents flow between all three ports simultaneously, which is a key differentiator from the T-type, which can allow this. This makes the L-type ideal for switching applications where distinct separation of paths is required, or where a specific bypass function is needed. For instance, in a heat exchanger system, an L-type valve can effectively divert the flow of cooling water from the exchanger to a bypass line for maintenance without disrupting the main process flow. This precise control minimizes operational downtime and maximizes system efficiency, underscoring its value as a fundamental component in complex industrial schematics. The robust design, often featuring a direct mounting pad for easy automation, further enhances its utility, allowing for seamless integration with pneumatic or electric actuators for remote and automated control, crucial for modern, highly regulated industrial environments. The versatility of the 3 way valve l type makes it a prime candidate when searching for a "3 way ball valve for sale" that provides critical functionality in a single, reliable unit, reducing installation complexity and potential leak points across varied applications.

The Advanced Manufacturing Process of High-Performance 3 way valve l type

The production of a high-quality 3 way valve l type involves a sophisticated multi-stage manufacturing process, meticulously designed to ensure durability, precision, and reliable performance under diverse industrial conditions. The journey begins with the selection of premium materials, which are critical for the valve's integrity and longevity. Common choices include various grades of stainless steel (such as SS304, SS316, 316L, and Duplex Stainless Steel like F51/F53 for enhanced corrosion resistance and strength), carbon steel (WCB, LCB for low-temperature service), and specialized alloys like Monel, Hastelloy, or Inconel for extremely corrosive or high-temperature applications. The choice of material is primarily driven by the media characteristics (corrosivity, temperature, pressure), operating environment, and specific industry standards (e.g., NACE MR0175 for sour gas service). Manufacturing processes typically involve either casting or forging for the valve body and end caps. Casting allows for complex shapes and is cost-effective for larger volumes, while forging provides superior mechanical properties, including higher strength and better resistance to fatigue and impact, making it ideal for high-pressure and critical applications. After the initial formation, precision CNC machining (Computer Numerical Control) is employed to achieve the exact dimensions, smooth surface finishes, and tight tolerances required for the ball, stem, and body connections. This highly automated process ensures perfect alignment of components, crucial for achieving tight shut-off and smooth operation. The ball's surface is often polished or coated (e.g., hard chrome plating, tungsten carbide) to reduce friction and enhance wear resistance, particularly important for frequent actuation cycles. The critical sealing components, such as seats and stem packing, are manufactured from materials like PTFE (Polytetrafluoroethylene), RPTFE (Reinforced PTFE), PEEK (Polyetheretherketone), or PCTFE (Polychlorotrifluoroethylene), selected based on temperature, chemical compatibility, and pressure requirements to ensure bubble-tight shut-off and minimize fugitive emissions. This meticulous material selection and initial forming process lay the groundwork for the exceptional longevity and resilience expected from a reliable 3 way valve l type.

Throughout the manufacturing cycle, stringent quality control and inspection standards are enforced to guarantee the valve's performance and compliance with international regulations. Key inspection phases include material verification (spectrographic analysis, mechanical property testing), dimensional checks, non-destructive testing (NDT) such as radiographic testing (RT) for internal flaws in castings/forgings, ultrasonic testing (UT), magnetic particle inspection (MPI), and liquid penetrant inspection (LPI) for surface defects. The most critical tests are the hydrostatic test (shell test and seat test) and pneumatic test (low-pressure air seat test, sometimes also high-pressure gas test), which verify the pressure-retaining capability of the valve body and the leak-tightness of the seats and stem packing, respectively. These tests are conducted in accordance with industry benchmarks like API 598 or ISO 5208. Furthermore, adherence to widely recognized international standards such as ISO 9001 (Quality Management Systems), ANSI/ASME B16.34 (Valves—Flanged, Threaded, and Welding End), API 6D (Pipeline Valves), and the PED 2014/68/EU (Pressure Equipment Directive for European markets) is paramount. These certifications ensure that the valve not only meets specific technical requirements but also adheres to robust quality management practices from design to delivery. The projected service life of a well-engineered 3 way valve l type is significantly extended through superior material selection and manufacturing precision, often exceeding industry expectations for typical operational cycles, particularly in applications where corrosion resistance and minimal maintenance are critical. For instance, in corrosive environments like those found in the petrochemical or chemical processing industries, the use of duplex stainless steel or specialized coatings dramatically enhances the valve's lifespan and reduces lifecycle costs. The advanced manufacturing processes also contribute to the valve's ability to offer energy efficiency by minimizing pressure drop across the valve, thereby reducing the energy required for fluid transportation, a key advantage in energy-intensive industries. Such rigorous processes differentiate a high-quality 3 way valve l type from lesser alternatives, ensuring reliability and long-term value.

Technical Parameters and Specifications of 3 way valve l type: A Data-Driven Overview

Selecting the appropriate 3 way valve l type requires a meticulous understanding of its technical parameters and specifications, which dictate its suitability for various industrial applications. These parameters define the valve's operational limits and ensure its compatibility with the system's design requirements. Key specifications typically include nominal diameter (DN/NPS), pressure rating, temperature range, body and trim materials, end connection types, and actuation options. The Nominal Diameter (DN) or Nominal Pipe Size (NPS) specifies the approximate inside diameter of the valve, corresponding to the piping system it will be installed in, ranging from small bore sizes like DN15 (1/2 inch) to very large sizes exceeding DN600 (24 inches) for specific industrial main lines. Pressure Rating indicates the maximum permissible operating pressure at a given temperature. This is typically expressed in Pressure Nominal (PN) for metric systems (e.g., PN16, PN25, PN40) or ANSI classes for imperial systems (e.g., Class 150, Class 300, Class 600, Class 900), determined by standards like ASME B16.34. A valve rated PN40 can handle up to 40 bar, while a Class 300 valve is designed for higher pressures than a Class 150 valve, emphasizing the importance of matching the valve to the system's maximum operating pressure to prevent catastrophic failures. The Temperature Range defines the minimum and maximum fluid temperatures the valve can safely handle, which is largely dependent on the body material, seat material (e.g., PTFE, PEEK, metal seats for high temperatures), and packing material. For instance, standard PTFE seats are generally limited to around 200°C (392°F), while PEEK can extend this to 260°C (500°F) or higher, with specialized metal seats capable of handling over 400°C (752°F). These detailed specifications are critical for ensuring the safe and efficient operation of any 3 way valve l type in its intended environment.

The selection of Body and Trim Materials is critical for chemical compatibility and resistance to corrosion and erosion. Common body materials include Stainless Steel (SS304, SS316, 316L), Carbon Steel (WCB, A105), and Alloy Steels, while trim materials (ball, stem, seats) are often similar to or more corrosion-resistant than the body, ensuring the internal components exposed to the fluid withstand harsh conditions. End Connection Types determine how the valve integrates with the piping system. Common types include flanged ends (ASME B16.5, EN 1092-1), threaded ends (NPT, BSPT), welded ends (socket weld, butt weld), and wafer or lug-type connections for compact installations. Each connection type offers distinct advantages in terms of installation ease, sealing integrity, and maintenance requirements. Lastly, Actuation Options allow for manual operation (lever, gearbox) or automated control via pneumatic, electric, or hydraulic actuators, especially when the 3 way valve l type is equipped with a direct mounting pad conforming to ISO 5211, facilitating seamless automation. Below is a detailed table summarizing typical specifications for a robust 3 way valve l type, providing a quick reference for technical decision-makers and procurement teams evaluating a "3 way ball valve for sale" that truly meets stringent industrial demands. This comprehensive overview aims to underscore the critical interplay between these parameters, highlighting how each specification contributes to the overall performance, safety, and longevity of the valve in its intended application, enabling users to make informed choices that optimize both operational efficiency and cost-effectiveness. When considering the options available, especially differentiating between a 3 way valve t type and an L-type, these specific parameters guide the selection based on flow path requirements. For instance, a high-pressure chemical application might demand a Class 900, 316L stainless steel valve with butt-weld ends and PEEK seats, whereas a low-pressure water treatment system might suffice with a PN16, WCB valve with threaded ends and PTFE seats. The precision in matching these details to application needs prevents costly failures and ensures long-term operational integrity of the 3 way valve l type.

| Parameter | Description | Typical Range / Options |

|---|---|---|

| Nominal Size (DN / NPS) | Diameter of the valve port, matching pipe size. | DN15 - DN600 (NPS 1/2" - 24") and larger for specific projects. |

| Pressure Rating | Maximum working pressure the valve can withstand. | PN16, PN25, PN40, PN63, PN100 (Metric); Class 150, 300, 600, 900, 1500 (ANSI). |

| Temperature Range | Operating temperature limits for media. | -29°C to +200°C (-20°F to +392°F) for soft seats (PTFE); up to +400°C (752°F) for PEEK/Metal seats. Cryogenic options available. |

| Body Materials | Material of the valve body for structural integrity. | WCB (Carbon Steel), LCB (Low Temp Carbon Steel), CF8/304, CF8M/316, CF3M/316L (Stainless Steel), Duplex SS (CD3MN/A890 4A), Alloy 20, Hastelloy, Monel. |

| Ball & Stem Materials | Materials for the internal flow control components. | SS304, SS316, 316L, Duplex SS, Alloy 20. Often polished or coated. |

| Seat Materials | Material providing the seal between ball and body. | PTFE, RPTFE (Reinforced PTFE), PEEK, PCTFE, Devlon, Metal seats (for high temperature/abrasive media). |

| End Connections | Method of connecting valve to piping. | Flanged (RF, FF, RTJ per ASME B16.5, EN 1092-1), Threaded (NPT, BSPT, G), Socket Weld (SW), Butt Weld (BW), Clamp, Wafer, Lug. |

| Bore Type | Internal bore configuration. | Full Bore (FB) for minimal pressure drop; Reduced Bore (RB) for cost-efficiency. |

| Actuation | Method of operating the valve. | Manual (Lever, Gearbox), Pneumatic (Double Acting, Spring Return), Electric (On/Off, Modulating), Hydraulic. ISO 5211 direct mounting pad for easy automation. |

| Design Standards | Industry standards followed for design and manufacturing. | API 6D, API 608, ASME B16.34, ISO 17292, NACE MR0175, PED 2014/68/EU. |

| Inspection & Test | Testing procedures for quality assurance. | API 598, ISO 5208 (Pressure Testing); NDT (RT, UT, MPI, LPI). |

Diverse Application Scenarios and Industry Trends for 3 way valve l type

The inherent versatility of the 3 way valve l type positions it as a critical component across a wide array of industrial sectors, each leveraging its unique flow diversion capabilities to optimize processes and enhance operational efficiency. In the Petrochemical and Chemical Industries, these valves are indispensable for managing the flow of various chemicals, hydrocarbons, and corrosive media. They are frequently employed in reactor systems for diverting feedstocks, in blending operations to select specific components, or in sampling lines to redirect process fluids for analysis. Their robust design and material compatibility, often involving stainless steel or exotic alloys, ensure reliable performance even in highly aggressive chemical environments, where corrosion resistance is paramount. Similarly, the Oil & Gas Sector utilizes L-type valves in manifold systems, pipeline diversions, and wellhead applications, where precise control over the flow of crude oil, natural gas, or refined products is crucial. The ability to switch between different lines or bypass sections of a system without interruption makes them invaluable for maintaining continuous operations and facilitating maintenance. In Water Treatment and Wastewater Management, 3 way valve l type valves are used to divert water between filtration stages, chemical dosing points, or different treatment tanks, contributing to efficient and effective purification processes. Their role in preventing cross-contamination and ensuring controlled flow paths is vital for public health and environmental protection. This broad applicability highlights why a quality "3 way ball valve for sale" is a vital consideration for diverse industrial needs.

Beyond these heavy industries, the 3 way valve l type also finds extensive application in the Food & Beverage and Pharmaceutical Industries, where stringent hygiene and contamination prevention standards apply. Here, polished internal surfaces and specific material certifications (e.g., FDA compliance for elastomers) are crucial. They are used for diverting cleaning-in-place (CIP) solutions, selecting ingredients for mixing, or directing products to different packaging lines, all while ensuring product integrity and preventing cross-contamination. Their quick quarter-turn operation and ease of automation are particularly beneficial in these fast-paced, highly regulated environments. In HVAC systems, L-type valves manage the flow of heating or cooling fluids in large commercial buildings, diverting water between chillers, boilers, or heat exchangers to optimize temperature control and energy consumption. This application directly translates into significant energy savings and improved comfort. The technical advantages in these typical application scenarios are manifold: energy saving through optimized flow paths that minimize pressure drop; superior corrosion resistance due to advanced material selection and surface treatments, ensuring extended operational life; and precise flow control that enhances process efficiency and product quality. Current industry trends are further amplifying the demand for advanced 3 way valve l type solutions. There's a growing emphasis on automation and digitalization, driving the demand for valves equipped with ISO 5211 mounting pads for seamless integration with pneumatic or electric actuators and intelligent control systems. The push for sustainability and environmental protection has increased the focus on valves with low fugitive emissions (e.g., ISO 15848-1 compliance) to reduce leakage of harmful substances. Furthermore, the rise of smart manufacturing and Industry 4.0 paradigms necessitates valves with advanced diagnostics and predictive maintenance capabilities, ensuring maximum uptime and operational safety. Manufacturers are responding by incorporating sensor technologies and digital communication protocols into valve designs, turning them into intelligent components of integrated control networks. This evolution underscores the continuous innovation in the design and application of these critical flow control devices, ensuring their relevance and indispensable role in the modern industrial landscape. This adaptability and ongoing technological advancement mean that a well-chosen 3 way valve l type is not just a component, but a strategic investment in long-term operational excellence, offering significant returns in terms of efficiency, safety, and environmental compliance.

Technical Advantages of Opting for a Robust 3 way valve l type

The decision to integrate a 3 way valve l type into an industrial system brings forth a multitude of technical and operational advantages that significantly contribute to efficiency, safety, and cost-effectiveness. One of the primary benefits is its unparalleled flow path flexibility. Unlike conventional 2-way valves that merely open or close a single path, the L-type configuration allows for the precise diversion of fluid from one inlet to either of two outlets (e.g., from a main line to a bypass, or from one source to one of two destinations). This eliminates the need for complex piping manifolds often comprised of multiple 2-way valves, check valves, and intricate pipe bends, thus achieving the desired flow control with a single device. This inherent simplicity translates directly into reduced piping complexity and consequently, a smaller installation footprint. By consolidating multiple functions into one valve, engineers can design more compact systems, which is crucial in space-constrained facilities or for mobile industrial units. The reduction in pipe length, fittings, and welding points inherently lowers material costs, installation time, and potential leak paths, leading to long-term space and cost efficiency. A single 3 way valve l type requires less maintenance attention than an equivalent setup of two or more 2-way valves, further contributing to operational savings and reduced downtime. This efficiency gain positions the L-type as a preferred solution for those seeking a highly effective "3 way ball valve for sale".

Furthermore, the robust design of modern 3-way ball valves, particularly the 3 piece ball valve construction, offers significant advantages in terms of sealing integrity and leakage prevention. The floating ball design, combined with resilient seat materials like PTFE or PEEK, provides excellent shut-off capabilities, minimizing the risk of internal or external leakage. This is critical for processes involving hazardous, expensive, or environmentally sensitive fluids, where fugitive emissions are a major concern. Adherence to standards like ISO 15848-1 for low fugitive emissions further underscores the superior sealing performance of a high-quality 3 way valve l type. The quarter-turn operation of ball valves ensures rapid opening and closing, which can be vital in emergency shut-down procedures or for precise timing in batch processes. This quick actuation reduces wear on internal components compared to multi-turn valves, contributing to a longer service life and reduced maintenance frequency. Finally, the growing trend towards automation readiness is seamlessly accommodated by the 3 way valve l type, especially those designed with an ISO 5211 direct mounting pad. This standardized interface allows for the quick and straightforward integration of pneumatic, electric, or hydraulic actuators, enabling remote control, integration into SCADA systems, and precise modulation of flow. Automated valves enhance operational safety by minimizing human intervention in hazardous areas, improve process accuracy through digital control, and facilitate efficient plant management through centralized monitoring. These cumulative technical advantages solidify the L-type 3-way ball valve's position as a preferred choice for industries seeking high-performance, reliable, and cost-effective flow control solutions that enhance both productivity and safety. The continuous innovation in materials science and manufacturing precision, combined with a focus on ease of automation, ensures that the L-type valve remains at the forefront of fluid management technology, addressing the evolving demands of complex industrial landscapes.

Manufacturer Comparison: Selecting the Right Partner for Your 3 way valve l type Needs

Choosing the right manufacturer for your 3 way valve l type is as critical as selecting the valve itself. The quality, reliability, and long-term performance of the valve are directly tied to the manufacturer's expertise, production capabilities, and commitment to customer satisfaction. When evaluating potential suppliers, B2B decision-makers and technical personnel should consider several key criteria to ensure a wise investment, particularly when exploring options for a "3 way ball valve for sale". Foremost among these are certifications and compliance. A reputable manufacturer will possess internationally recognized certifications such as ISO 9001 for quality management systems, indicating a consistent approach to product quality from design to delivery. Furthermore, compliance with specific product standards like API 6D (for pipeline valves), ASME B16.34 (for steel valves), and regional directives like PED 2014/68/EU (for pressure equipment in Europe) demonstrates adherence to rigorous technical and safety requirements. Beyond certifications, the manufacturer's experience and track record in the industry are vital. Longevity in the market often signifies a deep understanding of fluid control challenges and a proven ability to deliver reliable solutions. Look for manufacturers with a long history of serving diverse industries, as this indicates adaptability and a broad range of application knowledge. For example, Houde Valve, with its extensive years of experience, has established itself as a reliable partner in industrial valve manufacturing, providing robust 3 way valve l type solutions that meet the demanding requirements of various sectors, from petrochemical to water treatment.

Another crucial aspect is the manufacturer's Research and Development (R&D) capabilities. A forward-thinking company continuously invests in R&D to innovate designs, improve material performance, and incorporate new technologies like smart valve features or advanced coatings. This commitment ensures that their products remain at the forefront of technological advancement, offering enhanced efficiency, safety, and environmental performance. Customer support and after-sales service are equally important considerations. A strong manufacturer provides comprehensive technical assistance, prompt responsiveness to inquiries, and efficient after-sales support, including spare parts availability, troubleshooting, and field service. This ensures that any operational issues are quickly resolved, minimizing downtime and maximizing the return on investment. Furthermore, the ability to offer customization and tailored solutions is a significant differentiator. While standard 3 way valve l type models serve many applications, specific industrial processes often require bespoke modifications in terms of materials, sizes, pressure ratings, or actuation mechanisms. A manufacturer capable of providing engineered-to-order solutions demonstrates a high level of technical proficiency and commitment to meeting unique client needs, whether it's for specialized corrosive media or extreme temperature conditions. Finally, it's beneficial to assess the manufacturer's supply chain robustness and delivery consistency. Timely delivery and efficient logistics are critical for project schedules and operational continuity. A manufacturer with a well-managed supply chain can ensure that your 3 way valve l type products are delivered on time and in perfect condition, preventing costly delays. By meticulously evaluating these criteria, B2B stakeholders can confidently select a manufacturing partner like Houde Valve that not only supplies high-quality 3 way valve l type products but also provides comprehensive support and expertise throughout the entire lifecycle of the valve. This strategic partnership contributes significantly to operational excellence and long-term success. The reputation of a manufacturer, often evidenced by client testimonials and repeat business, should also be a guiding factor, offering tangible proof of their reliability and commitment to forging lasting relationships built on trust and superior product delivery.

Customization and Tailored Solutions for Specific Industrial Demands

While standard configurations of the 3 way valve l type are widely available and suitable for many applications, the complexity and diversity of modern industrial processes frequently necessitate highly customized solutions. Recognizing that a one-size-fits-all approach is insufficient for optimal performance in niche or extreme environments, leading manufacturers like Houde Valve specialize in offering tailored valve solutions designed to meet precise operational demands. This customization capability is a critical advantage, enabling clients to acquire valves that are perfectly integrated into their unique systems, rather than making compromises with off-the-shelf products. The scope of customization often extends across several key areas, starting with custom materials. For applications involving highly corrosive chemicals, abrasive slurries, or extreme temperatures, standard stainless steel or carbon steel may not suffice. Manufacturers can provide valves constructed from exotic alloys such as Hastelloy, Monel, Inconel, Titanium, or various grades of Duplex and Super Duplex Stainless Steel (e.g., F55), offering superior resistance to specific chemical attack or enhanced mechanical strength at elevated temperatures. For instance, NACE MR0175 compliance for sour gas service is a common requirement for valves in oil and gas production, necessitating specific material compositions and hardness controls to prevent sulfide stress cracking. Such material customizations ensure the longevity and integrity of the 3 way valve l type in challenging conditions.

Beyond materials, customization extends to specific sizes and pressure ratings outside the standard ranges. This includes exceptionally large diameter valves for main pipeline applications or small, highly specialized valves for precision dosing in pharmaceutical processes. Similarly, valves can be engineered to handle ultra-high pressures exceeding Class 1500 or cryogenic temperatures down to -196°C (-320°F) for applications like LNG (Liquefied Natural Gas) storage and transfer. Specialized end connections are another area of customization; while flanged and threaded ends are common, unique system designs might require specific welding configurations (e.g., extended butt weld ends for direct pipeline integration), hygienic clamp connections for sanitary applications, or custom adaptors. Furthermore, tailored actuation and control accessories can be provided. This includes integrating specific types of actuators (pneumatic, electric, hydraulic) with unique control functionalities (e.g., modulating control for precise flow regulation, limit switches for position feedback, solenoid valves for remote operation), often pre-assembled and factory-tested on the direct mounting pad of the 3 way valve l type. For applications with strict environmental regulations, valves can be customized for low fugitive emissions (LFE), featuring advanced stem packing designs and testing to ISO 15848-1, significantly reducing leakage to the atmosphere. Other customizations might include specialized coatings for abrasive service, extended bonnets for cryogenic or high-temperature applications to protect the packing, locking devices for security, or specific bypass mechanisms. The ability to provide these tailored solutions demonstrates a manufacturer's deep engineering expertise and their commitment to optimizing client operations. By working closely with customers, reputable valve manufacturers ensure that every aspect of the valve's design and construction is perfectly aligned with the demanding conditions and operational objectives of the specific application, leading to superior performance, reduced operational risks, and a longer overall service life for the critical 3 way valve l type component. This bespoke approach transforms the valve from a mere commodity into a precisely engineered tool, vital for the success of complex industrial projects.

Real-World Application Cases: 3 way valve l type in Action

The theoretical advantages of the 3 way valve l type truly manifest in its practical application across various industries, where it solves complex flow management challenges with elegant simplicity and robust performance. Understanding these real-world scenarios provides concrete evidence of its indispensable role.

Case Study 1: Chemical Blending and Diversion in a Pharmaceutical Plant

In a pharmaceutical manufacturing facility, precise and contamination-free handling of various active pharmaceutical ingredients (APIs) and excipients is critical. A leading pharmaceutical company implemented automated 3 way valve l type valves to manage the blending process of different precursor chemicals into a reaction vessel. Traditionally, this required a series of 2-way valves and complex manifold piping to switch between different ingredient tanks. By installing L-type valves, each connected to a specific ingredient line and the main reaction vessel, the facility achieved a highly streamlined system. The L-type valves with their L-bore configuration allowed for selective diversion: one inlet (from an ingredient tank) could be directed to either the reaction vessel or a bypass/drain line for cleaning-in-place (CIP) procedures. This setup significantly reduced the piping footprint, minimized potential leak points, and crucially, prevented accidental cross-contamination between different chemical streams due to the positive shut-off characteristic of the L-bore. The valves, made from sanitary 316L stainless steel with FDA-compliant PTFE seats and polished internal surfaces, ensured compliance with stringent pharmaceutical quality standards. Automation via electric actuators integrated with the plant's PLC system allowed for precise, repeatable, and remote control of ingredient dosing, greatly enhancing process efficiency and product consistency while maintaining the highest levels of sterility and safety. This example highlights the 3 way valve l type's ability to simplify complex fluid routing and ensure product purity in sensitive applications. This is why when considering a "3 way ball valve for sale" for a pharmaceutical context, the L-type is often the preferred choice.

Case Study 2: Heat Exchanger Bypass in an Industrial Cooling System

A large industrial facility relies on a continuous cooling system with multiple heat exchangers to regulate the temperature of process fluids. During routine maintenance or in the event of an unexpected fault with one heat exchanger, it's essential to bypass it without interrupting the overall cooling circulation. Here, the 3 way valve l type proves invaluable. An L-type valve is strategically placed at the inlet of each heat exchanger, with its three ports connected to: 1) the main incoming cooling water line, 2) the inlet of the heat exchanger, and 3) a bypass line that routes water directly back to the main return. When the heat exchanger is operational, the valve directs flow from the main line to the heat exchanger. When maintenance is required, a simple 90-degree rotation of the valve's ball diverts the entire cooling water flow through the bypass line, completely isolating the heat exchanger without any shutdown of the main cooling system. This seamless diversion mechanism drastically reduces downtime and allows maintenance personnel to safely access the equipment. The valves used were high-pressure, Class 300 carbon steel models with robust stem packing to prevent leakage of the circulating water. The direct mounting pads allowed for pneumatic actuation, enabling rapid and reliable switching operations from a central control room. This application demonstrates how the L-type valve facilitates uninterrupted operations and safe maintenance, contributing significantly to the overall reliability and availability of critical industrial infrastructure. It shows how the 3 way valve l type provides efficient bypass capabilities not possible with a typical 3 way valve t type.

Case Study 3: Filtration System Routing in a Water Treatment Plant

In a municipal water treatment plant, filtration systems often consist of multiple filter beds that require periodic backwashing or cleaning cycles. To ensure continuous water supply, the incoming raw water needs to be directed to operational filter beds while others are taken offline for maintenance or backwash. The 3 way valve l type is perfectly suited for this dynamic routing. For each filter bed, an L-type valve controls the incoming water supply. One port receives raw water, another directs it to the filter bed, and the third port is connected to a bypass manifold that can route water to other active filter beds. During normal operation, water flows into the designated filter. When a filter requires backwashing, the L-type valve rotates, diverting the raw water flow away from that specific filter and directing it to the manifold connected to other active filters, ensuring uninterrupted treatment capacity. Simultaneously, a separate valve system manages the backwash flow. The valves employed were large diameter, full bore, flanged-end versions, typically made from ductile iron or stainless steel for corrosion resistance against treated and untreated water. Their quarter-turn operation and the ability to automate them with electric actuators made the process of switching filter beds efficient and reliable, reducing manual labor and potential for human error. This case exemplifies the L-type valve's utility in managing distributed flow in large-scale utility operations, optimizing resource utilization and ensuring continuous service. These application examples underscore the practical value and versatility of the 3 way valve l type, showcasing its critical role in enhancing efficiency, safety, and reliability across diverse industrial landscapes. The robustness of a 3 piece ball valve construction further enhances its suitability for such demanding water treatment applications.

Ensuring Trust and Reliability: Quality Assurance and Customer Support

For B2B buyers and technical professionals, the decision to invest in a 3 way valve l type extends far beyond its initial purchase price; it encompasses the long-term reliability, support, and trust placed in the manufacturer. A reputable supplier understands that product quality is paramount and that robust customer support is essential for operational continuity. Manufacturers like Houde Valve build this trust through rigorous quality assurance protocols, transparent processes, and comprehensive after-sales services.

Frequently Asked Questions (FAQ) about 3 way valve l type

Q1: What is the fundamental difference between an L-type and a T-type 3-way ball valve?

A1: The key difference lies in the bore configuration of the ball. An 3 way valve l type (L-port) allows flow from one inlet to either of two outlets, diverting the flow. It never connects all three ports simultaneously. Conversely, a 3 way valve t type (T-port) can connect all three ports at once (allowing flow from two inlets to one outlet, or one inlet to two outlets, or through all three simultaneously) or can divert flow, making it suitable for mixing or distributing applications. The L-type is ideal for switching/diverting, while the T-type offers more complex flow patterns, including full straight-through flow. This distinction is critical when choosing a "3 way ball valve for sale" based on specific flow requirements.

Q2: How do I choose the correct material for my 3 way valve l type?

A2: Material selection is crucial and depends on the specific media (fluid) characteristics, including its chemical composition, temperature, and pressure. Corrosive fluids require stainless steel (SS316L, Duplex) or exotic alloys (Hastelloy, Monel). Abrasive fluids might need hardened ball and seat surfaces. For high temperatures, PEEK or metal seats are necessary, while cryogenic applications demand specialized low-temperature carbon steel or stainless steel. Always consult the manufacturer's material compatibility charts and your process specifications to ensure optimal performance of the 3 way valve l type.

Q3: What level of maintenance is typically required for a 3 way valve l type?

A3: Ball valves are generally considered low-maintenance devices due to their simple, robust design and self-lubricating seat materials. However, periodic inspection of stem packing for fugitive emissions, verification of tight shut-off, and lubrication of actuators (if automated) are recommended. For 3 piece ball valve designs, in-line maintenance and seat/seal replacement are significantly simplified, extending the valve's service life without removing it from the pipeline. Regular cycling of the valve, even when not actively required for process control, can also help prevent seat accumulation and ensure smooth operation of the 3 way valve l type.

Q4: Can these valves be easily automated?

A4: Yes, absolutely. Most high-quality 3 way valve l type products, especially those designed for industrial applications, come with an ISO 5211 direct mounting pad. This standardized interface allows for quick, secure, and cost-effective mounting of various actuators, including pneumatic (air-driven), electric, or hydraulic actuators, enabling remote control and integration into automated process control systems (DCS/SCADA). Automation enhances operational safety, precision, and efficiency, especially in critical or frequently switched applications, making the 3 way valve l type a flexible solution for modern process control.

Delivery Timelines and Quality Assurance Promises

Understanding the delivery cycle is crucial for project planning. Standard 3 way valve l type models typically have lead times ranging from 2-4 weeks, depending on size, material, and current production load. However, highly customized or large-volume orders may require longer lead times, usually communicated upfront. Reputable manufacturers provide clear delivery schedules and strive to meet them, ensuring that clients can maintain their project timelines. Houde Valve is committed to transparent communication regarding lead times and employs robust logistics to ensure timely and secure delivery worldwide for every 3 way valve l type. Our commitment to quality is underpinned by adherence to global standards, including ISO 9001 certification, which covers our entire manufacturing process from raw material inspection to final product testing. Each 3 way valve l type undergoes rigorous testing, including hydrostatic shell and seat tests (per API 598 or ISO 5208), pneumatic seat tests, and often additional functional tests to ensure zero leakage and optimal performance. Documentation, including Material Test Certificates (MTCs), hydrostatic test reports, and compliance certificates (e.g., CE marking for PED compliance), is provided with every shipment, offering complete traceability and assurance of quality. This meticulous process ensures that every "3 way ball valve for sale" from our facilities meets the highest industry benchmarks.

Comprehensive Warranty and Customer Support

A reliable manufacturer stands behind its products with a clear warranty commitment. Typically, a 3 way valve l type will come with a warranty period, often 12 to 24 months from installation or 18 months from shipment, covering defects in material and workmanship. This warranty provides clients with peace of mind, knowing that their investment is protected. Beyond the warranty, proactive customer support is a cornerstone of trustworthiness. This includes readily available technical assistance for installation, operation, and troubleshooting. Whether through dedicated support lines, email, or online portals, prompt and knowledgeable responses are vital. Furthermore, after-sales service encompassing spare parts availability, maintenance guidelines, and potential on-site support for complex issues or large installations ensures the long-term operational success of the valves. Manufacturers like Houde Valve prioritize building lasting relationships with clients, providing continuous support and expert advice throughout the entire lifecycle of the 3 way valve l type, from initial selection and customization to installation, operation, and eventual maintenance. This holistic approach to client service ensures that industrial operations can proceed with confidence, minimizing risks and maximizing efficiency, thereby establishing a foundation of trust that extends beyond just the product itself to the entire customer experience. Our commitment makes every "3 way ball valve for sale" a reliable and supported investment.

Conclusion: The Indispensable Role of Advanced 3 way valve l type Solutions

In summation, the 3 way valve l type stands as a cornerstone in modern industrial fluid control systems, offering unparalleled versatility, efficiency, and reliability for applications demanding precise flow diversion or selection. Its unique L-bore configuration simplifies complex piping layouts, reduces installation costs, and minimizes potential leak points, making it a superior alternative to multi-valve assemblies. From the meticulous selection of raw materials like high-grade stainless steel and specialized alloys to advanced manufacturing processes encompassing casting, forging, and precision CNC machining, every stage of its production is geared towards delivering a robust and long-lasting product. Stringent quality control measures, including NDT and hydrostatic/pneumatic testing to international standards such as ISO, ANSI, and API, ensure that each 3 way valve l type meets the highest benchmarks for performance and safety. The widespread application across diverse sectors—including petrochemical, chemical, oil & gas, water treatment, and food & beverage—underscores its adaptability and the significant advantages it offers in terms of energy efficiency, corrosion resistance, and operational flexibility.

The technical prowess of the 3 way valve l type is further enhanced by its inherent design, which allows for rapid quarter-turn actuation and seamless integration with automation systems via ISO 5211 direct mounting pads. This readiness for automation is critical in an era driven by Industry 4.0 and smart manufacturing initiatives, where remote control and predictive maintenance are becoming standard. Moreover, the availability of extensive customization options—from specialized materials for extreme conditions to bespoke end connections and actuation accessories—ensures that these valves can be precisely tailored to the most demanding and unique industrial requirements. Real-world application cases powerfully illustrate how these valves solve critical challenges, whether it's ensuring contamination-free chemical blending, facilitating uninterrupted heat exchanger maintenance, or optimizing filtration system routing. Ultimately, choosing a reputable manufacturer like Houde Valve, distinguished by its proven expertise, comprehensive quality assurance, transparent delivery cycles, and dedicated customer support, is crucial for securing a high-performance 3 way valve l type solution. This strategic partnership provides not just a product, but a complete solution backed by authority, experience, and trust, ensuring long-term operational excellence and a significant return on investment for B2B stakeholders who prioritize efficiency, safety, and reliability in their fluid management systems, whether they are looking for a 3 way ball valve for sale or require a specialized 3 piece ball valve or a 3 way valve t type.

References and Further Reading

- Valve Standards & Certifications: ISO 9001: Quality Management Systems - International Organization for Standardization Details the criteria for a quality management system.

- Industrial Valve Design Principles: ASME Journal of Pressure Vessel Technology A peer-reviewed journal often featuring articles on valve design and performance.

- Fluid Control Systems in Process Industries: Flow Control Network An industry resource for news, articles, and product information on fluid handling.

- Materials for Corrosive Applications: NACE MR0175/ISO 15156: Materials for use in H2S-containing Environments Standard providing guidelines for material selection in sour service environments.

- Actuator Integration Standards: ISO 5211: Industrial valves - Part-turn valve actuator attachments Specifies dimensions for mounting actuators to industrial valves.